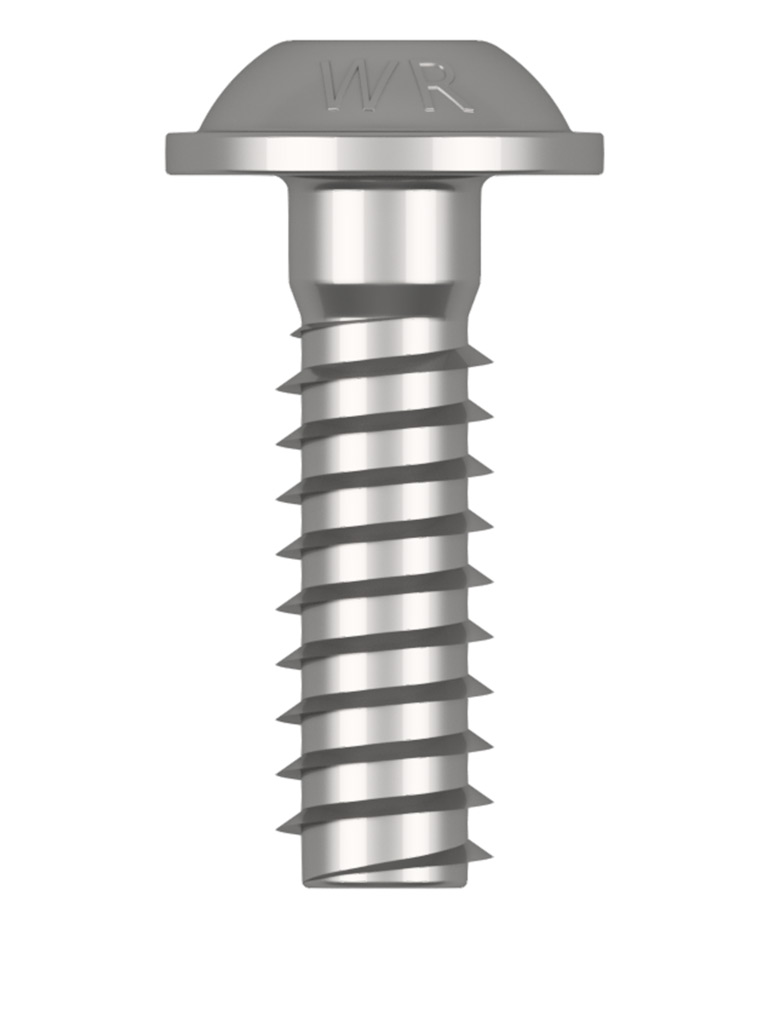

WR®-KT and WR®-KTPlus® thread

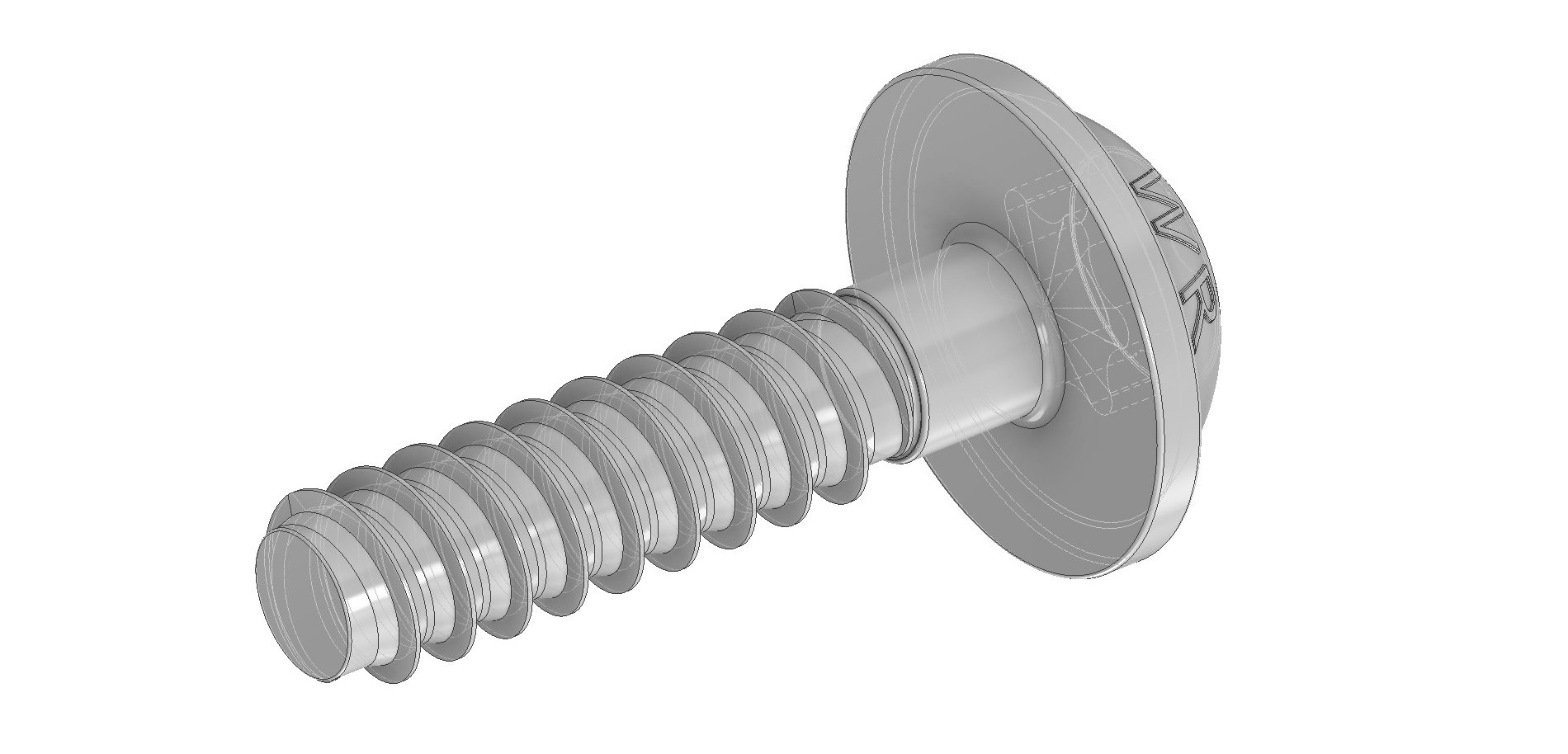

WR®-KT

Thread forming fasteners – the better economical solution

Created to form the internal thread into plain holes. The thread is formed by the screw itself by deformation of the thermoplast material. It guarantees an optimum contact between the screw thread and material.

WR®-KT standards

- WR®-KT 190 - 40°

- WR®-KT 195 - 30°

- WR®-KT 196 - 30°

Benefits:

- Eliminates costs of thread cutting

- Internal thread forming

- High tensile and torsion strength

- Material:

- Steel: grade 10.9 / case hardened

- Stainless steel: 1.4016 and 1.4567

Alternative geometry WR®-PTF is possible.

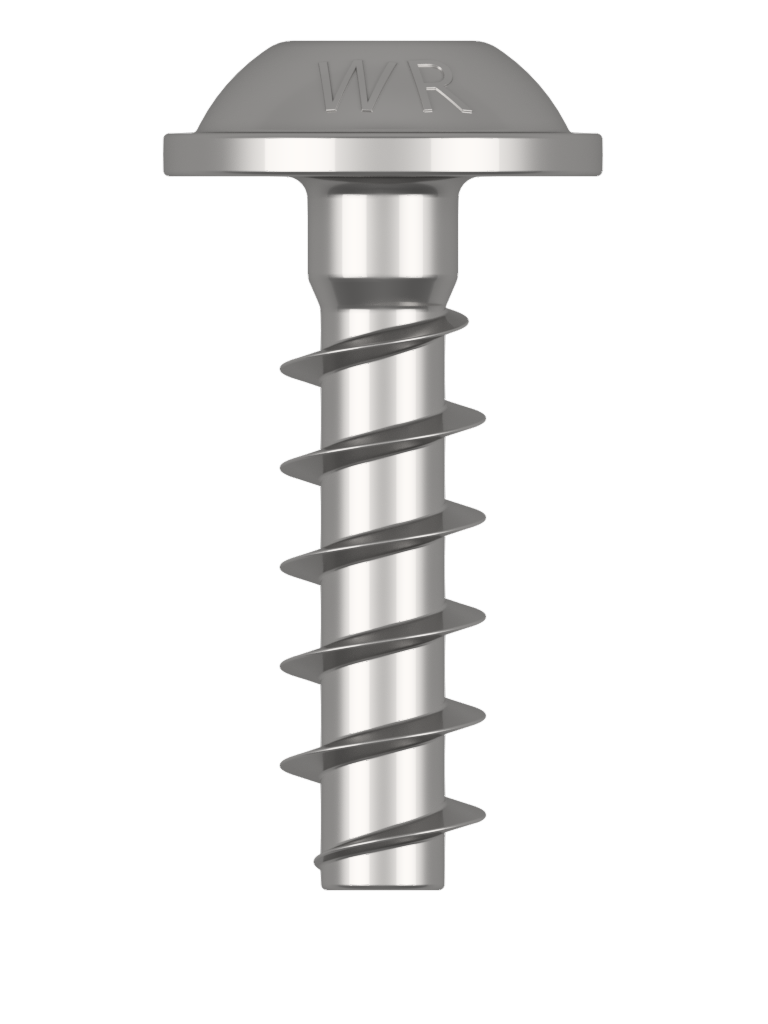

WR®-KTPlus® 250

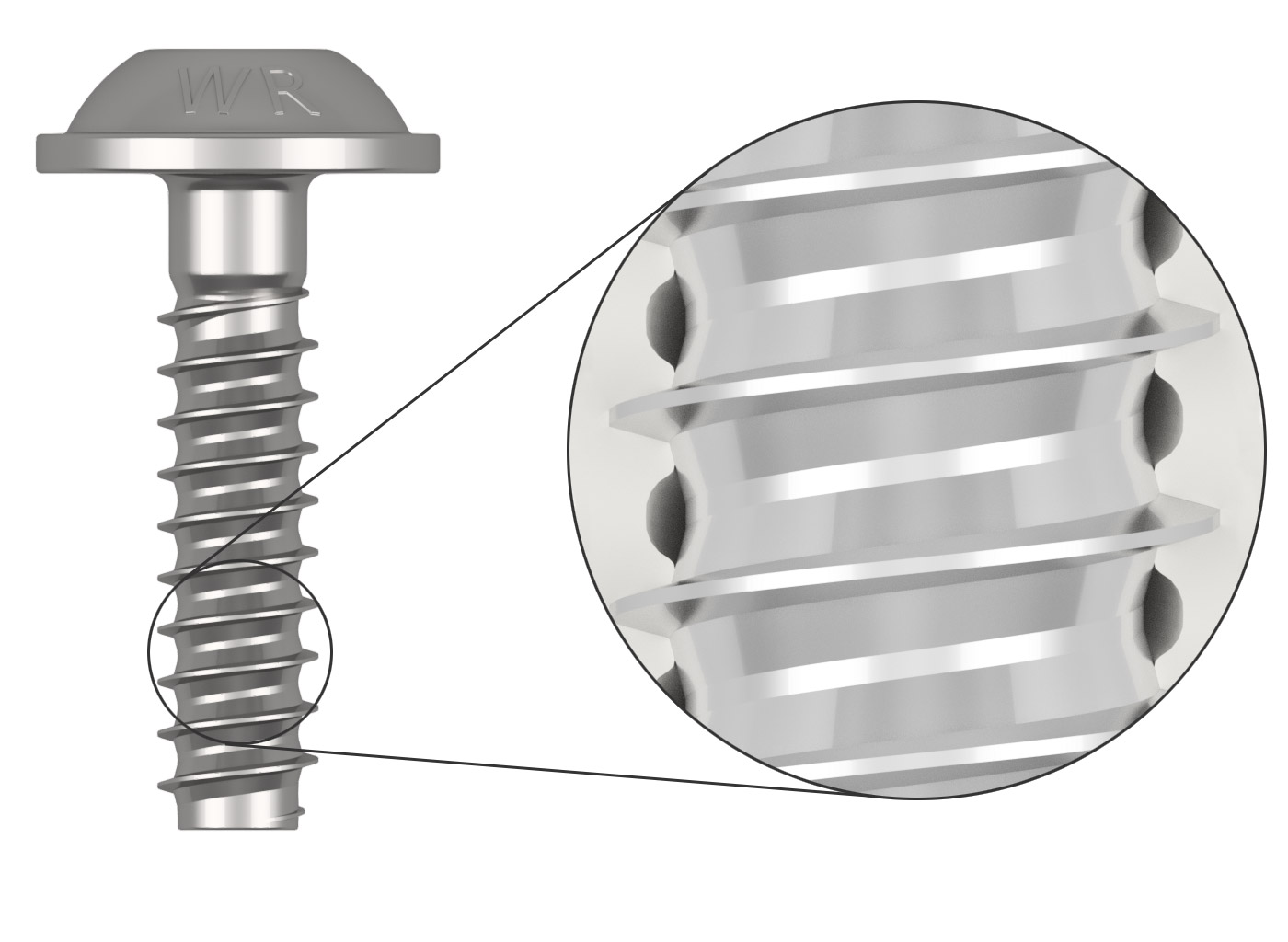

Patent since 04.07.2019 - our improvement for thread forming fasteners. WR® is the next evolution of our WR®-KT thread with additional benefits:

- 30° flank angle

- Slight radial stress

- Optimum material flow

- High clamp loads

- High tensile and torsion strength

- High strength under vibration

- Long lifetime of the connection

- Reduction of fastener length and/ or diameter = material savings

- Material:

- Steel: grade 10.9

- Stainless steel: 1.4016 and 1.4567

Alternative thread geometry WR®-DTP is possible.